PCB Design Services

PCB Design Services

We offer comprehensive PCB Design services using expertise gained over many years, and based at our UK site. Taking your initial concept, RVL uses Altium for schematic capture and PCB designs. (Altium is one of the latest and most effective CAD tools.) Alongside this, we insist on observing the “Design for Manufacture (DfM)” rules that are often overlooked by “design-only” companies.

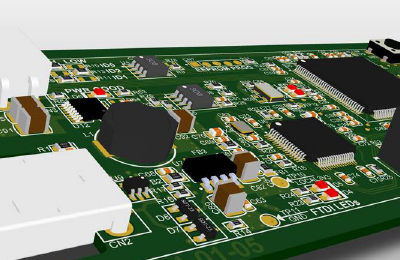

All schematics are designed while adhering to these strict rules. We always strive to provide elegant and simple solutions. However, when designing a PCB, we must also take into account power requirements, voltage restrictions, required communication interfaces etc. All PCBs are subject to stringent rule checking. For example, track clearance violations, high-speed routing impedances, 3D component clearances, silkscreen and solder mask checking, and netlist verification. If you need an existing PCB design revised or modified, we are very happy to advise you. Of course, we prefer to work together to find the best approach. Our engineers can work from existing design files, or start from scratch, but we will supply you with a complete manufacturing data pack with your finished PCB designs.

As part of RVL’s PCB design services, we will include in your data pack: the Bill of Materials (BOM), complete schematic and PCB design files in both PDF and Altium format, manufacturing Gerber files, drill files, Pick & Place files, assembly diagrams and a STEP-created 3D PDF file (showing a complete PCB design with components that can be rotated and viewed from every angle).

Our electronics design engineers can supply this 3D PDF file with or without an enclosure, providing reassurance that the PCB does indeed fit inside the enclosure. A useful feature is that this can be made transparent for various viewing options, as can any of the component STEP models included with the design.